Ergonomics

It’s not about making someone adapt to a poor work station set-up or poorly-designed equipment and tools. Nor is it the kind of pseudo-ergonomic “solution” that does not allow any kind of adjustment or flexibility.

- carpal tunnel syndrome

- rotator cuff injury

- tennis elbow/epicondylitis

- DeQuervains

- tenosynovitis

- back injuries

- bursitis

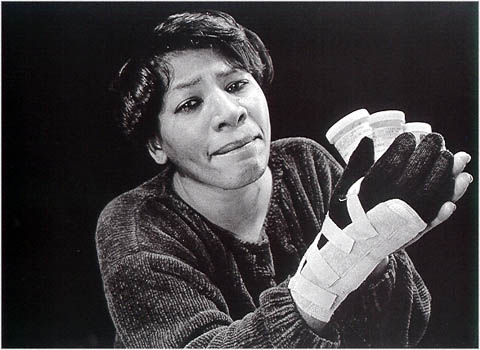

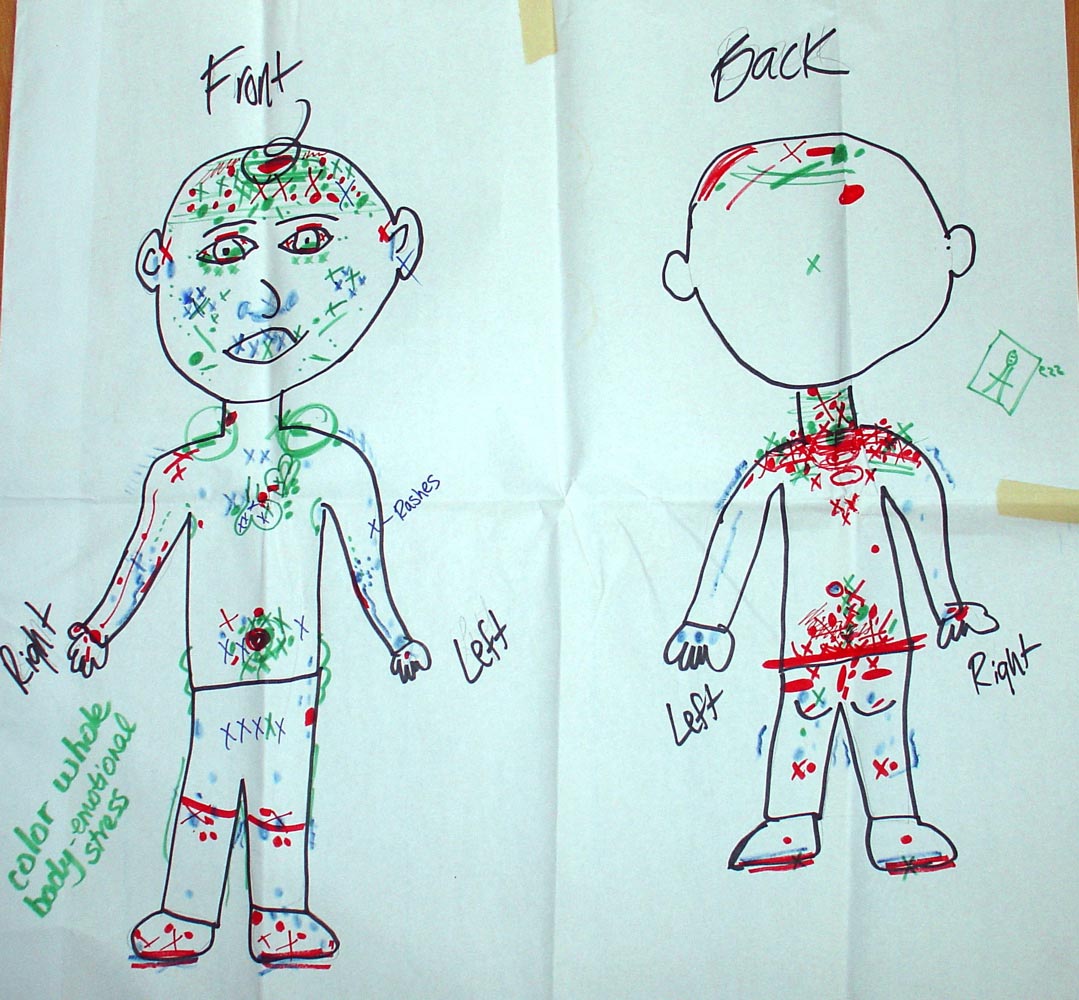

Whatever you call it, MSDs can cause a lot of pain. When wear and tear reaches a certain point, the result is a disability. It can be short-term but many take a long time to heal, partly because the hazard is not fixed. Sometimes, the damage is permanent.

Whether it lasts a long time or a short time, an MSD affects life on and off the job. Everyday activities can be difficult or impossible — opening a jar, chopping an onion, driving a car, lifting a child, turning a door knob, getting dressed, and holding a toothbrush.

MSDs regularly account for the largest percentage of reported compensation cases in Canada and other countries. In Manitoba, they accounted for just over 60% of injuries reported to the Compensation Board in 2016.

Unlike the United States, many countries have ergonomic regulations requiring attention to prevention of MSIs/MSDs. (The exceptions in the US are the relatively-new California regulation to affecting hotel housekeepers and Washington State’s ). Manitoba’s “Musculoskeletal injuries” regulation — it does not mention “ergonomics” — is unique for requiring evaluation of “fixes” to ensure they actually work.

We know a lot about good ergonomic design, the prevention measures that will stop these MSDs. Whether it’s for computer users or construction workers, we’ve known about good solutions for a long time. For more, see Ergonomic design assessments on this website.

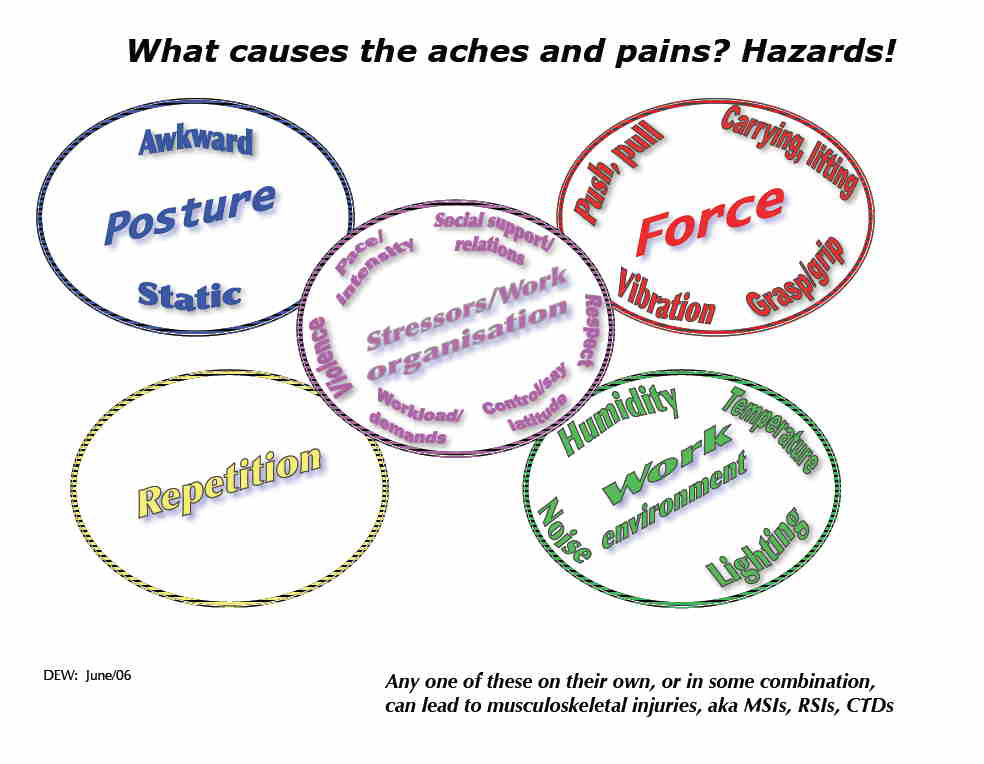

Ergonomic design hazards

Force:

The amount of pressure a person uses for a task. It includes pushing, pulling, lifting and even using a computer keyboard. Force puts a strain on the body and can cause damage to body parts or tissues.

Examples of force include:

- lifting heavy boxes

- the grasp or grip used to hold something (avoid pinch grips)

- computer keyboard work

- jack hammer (vibration)

- resting palm of hand or wrist on a tool handle or edge of something

Posture:

Examples of posture hazards include:

- working with arms above your head (awkward; also static if it lasts)

- working with bent joints (awkward; also static if it lasts)

- standing or kneeling for a while (static)

- working with your neck cricked to see the computer screen (awkward and static)

Repetition:

This means doing the same motion over and over, without adequate rest — even mini- breaks. Repetition “overuses” the same muscles, tendons, and other soft tissues. It can irritate tendons and increase pressure on nerves and may cause permanent damage.

Examples of repetition include:

- traditional assembly line work

- data entry

- piecework sewing

Work environment:

These hazards are part of the general work environment; sometimes they are called physical hazards (related to energy sources). They include humidity, temperature, noise and light. People working in cold temperatures can get stiff and sore and more likely to drop things. Noise causes deafness and interferes with your ability to hear and understand people’s words and other sounds. Poor lighting can lead to traumatic injuries and poor postures as you try to read things (e.g. with glare).

Examples of work environment hazards include:

- working in a freezer

- working with cold objects

- outdoors work during the summer

- working indoors with low or high humidity

- work with or near loud machinery or equipment

Stressors/work organisation:

These are the things that stress us out, the often-invisible aspects of work.

The hazard category covers how people and technology work together to produce a product or provide a service. It’s about too much or too little workload or demands on your body and mind, and how much say or control you have about your work.

It always is the result of choices some people make about the “technical aspects” (production methods, technology, etc.) and “people aspects” (how people will use the technology, whether people will work alone or with others, etc.) of work.

Examples of stressors include:

- pace of work

- workload

- staffing levels

- hours of work

- supervision style

- production quotas

- deadlines

- number and length of rest breaks

- flexibility allowed for family and other responsibilities

- violence (including harassment, bullying and discrimination)

For example, if the speed of a job is increased to maximize production, workers likely have to do more work — more repetitive motions, perhaps in more static postures. In other situations, deadlines or production quotas can cause muscles to tense up, adding to “wear and tear” on soft tissues and increasing the risk of musculoskeletal disorders.

To figure out the connections between the other hazards and stressors, ask:

- but why? (five times); or

- what makes the symptoms worse?